Transforming How the World is Built®

The conventional approach to high-rise construction is full of inefficiencies that contribute to a significant decline in productivity. The construction industry has seen a 40% drop in productivity since 1970, largely due to the inability to efficiently convert intermediate goods into finished products. If construction productivity had grown at even a modest rate of 1% per year, overall labor productivity in the economy would be about 10% higher today, according to recent research (Goolsbee and Syverson, 2023). With productivity down and demand at an all-time high, 100-year-old general contractor Barton Malow set out to reverse the trend. At LIFTbuild, the future starts at the top.

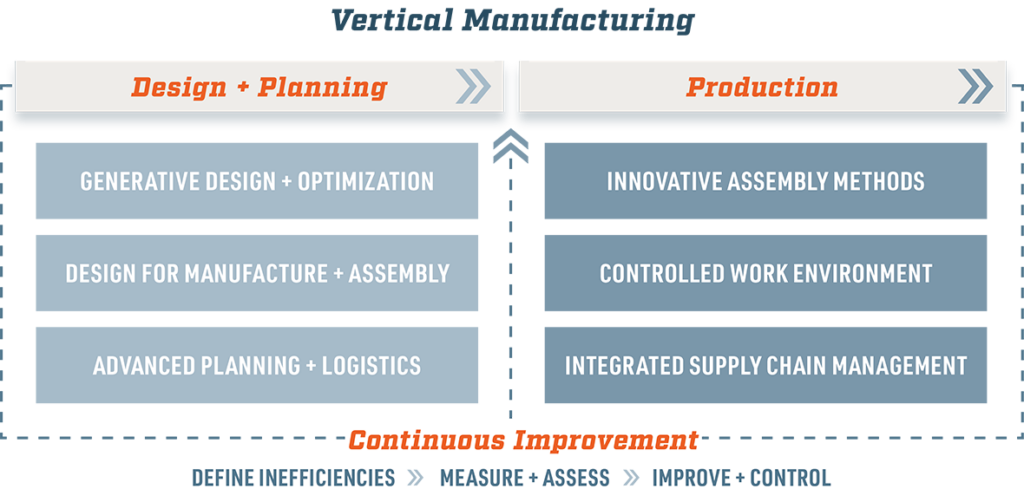

Drawing from the ingenuity of the automotive assembly line, the manufacturing environment is at the heart of LIFTbuild’s approach from design through construction. With Vertical Manufacturing™, there are limitless opportunities to take advantage of design, construction, and operation standardization. LIFTbuild is optimized for buildings 12 stories or higher in the residential, mixed-use, hospitality, office, healthcare, and technology/research markets.

Integrated Team + Manufacturing Principles

Our integrated design-build approach hinges on early engagement with key stakeholders, a seamless flow of information for timely decision-making, and a focus on innovation and continuous improvement. To deliver successful building construction services and a positive experience for all stakeholders, we foster a culture of teamwork and collaboration throughout the entire project lifecycle.

Beginning with Validation, LIFTbuild leverages generative design to test potential opportunities and empower clients with the insights needed to drive programmatic and financial success. Once project viability is established, LIFTbuild takes on the role of design-builder, bringing together all necessary partners for Design + Planning, including key alliance subcontractors. The design is optimized and customized while maintaining a focus on designing for manufacture and assembly (DfMA), taking advantage of prefabrication and modularization opportunities. This collaborative approach has proven invaluable for the swift procurement and design decisions that align with LIFTbuild’s assembly pace.

During Production, the meticulous planning of material delivery and unique assembly process comes to life in a controlled work environment, creating a literal vertical assembly line. After building structural spines and lifting the roof plate into place, LIFTbuild manufactures tall buildings one floor at a time on the assembly pad before lifting each floor to its final height above. The repetitive nature and focus on continuous improvement ensures project teams reach maximum efficiency on site.

LIFTbuild’s Vertical Manufacturing™ proprietary service offering ensures a smooth and predictable process that delivers safe, high-quality construction projects quickly. Learn more about the benefits of a LIFTbuild project.